T11 T12 T22 T91 T92 Alloy Steel Seamless Paipu

hana hana

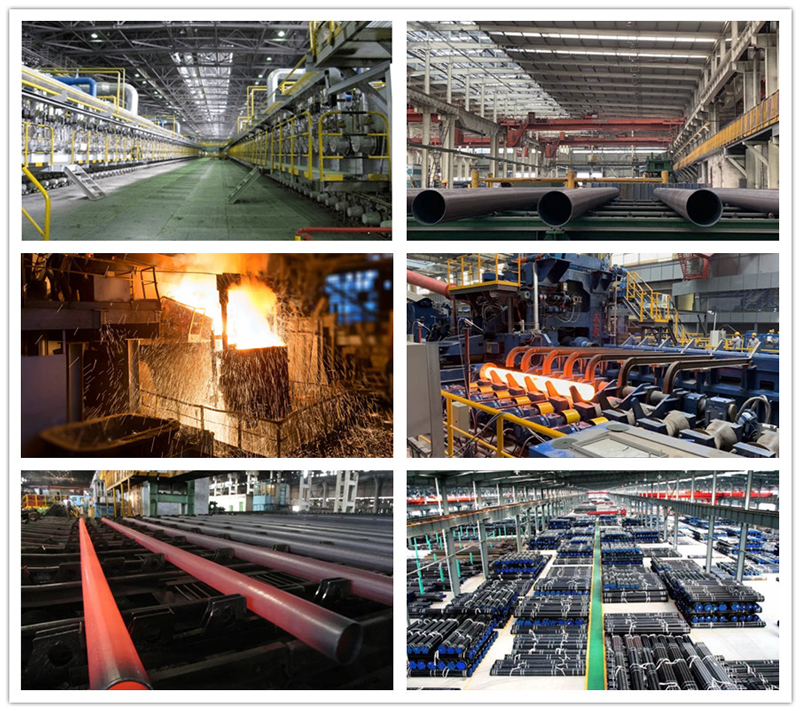

ʻO ka ʻōwili wela (paipu kila maʻemaʻe i hoʻokuʻu ʻia): ka paipu pōʻai billet mehana perforation ʻekolu roll inclined rolling, hoʻomau i ka ʻōwili ʻia a i ʻole ke anawaena hoʻokuʻu ʻia (a i ʻole ke anawaena hoʻemi ʻia) hōʻailona hoʻāʻo hydraulic hoʻomaʻamaʻa hoʻoluʻu (a i ʻole flaw) no ka mālama ʻana.

Paipu huki anu ('ōwili) paipu kila maʻemaʻe: puʻu pōʻai billet i hoʻomehana ʻia, poʻo ʻūhā, annealing, pickling a me ka ʻaila i uhi ʻia (copper plating) multi-channel anu huki huki paipu (cold rolled) billet pipe heat treatment straightening hydraulic test (flaw detection) mark i loko o kahi waihona.

I ke kaʻina hana o ka paipu kila maʻemaʻe no ka paila, ʻo ka mālama wela ke kaʻina hana nui.He hopena koʻikoʻi ka hoʻomaʻamaʻa wela i ka maikaʻi o loko a me ka maikaʻi o ka ʻili o ka paipu kila maʻemaʻe, ʻo ia ka mea nui no ka hana ʻana i ka paipu kila seamless.

Hoʻohana kā mākou hui i ka mālama wela non-oxidation, ka hana ʻana i nā paipu kila me ka hui metallographic paʻa a me ka maikaʻi o loko a me waho, me ka hoʻohana ʻana i ka eddy current a me ka ultrasonic automatic flaw detection, steel pipe one by one for eddy current flaw detection and ultrasonic flaw detection.Me ke ana mānoanoa kani ultrasonic a me ka oblique flaw detection functions, hiki iā ia ke ʻike pono i nā hemahema i hoʻopaʻa ʻia i loko o ka paipu kila.

ʻO ke ala nānā maikaʻi o ka paipu kila ʻole

1. Ka nānā 'ana i ka haku mele 'ana: ke 'ano o ka ho'ā'o 'ana kemika, ka nānā 'ana i ka mea kani (mea kani CS infrared, ka spectrometer heluhelu pololei, zcP, etc.).

2. Nānā maikaʻi o ka ʻili o ka paipu kila: 100%

A. ʻIke kani ultrasonic UT:

B. ET: (induction electromagnetic)

C. MT a me ka ʻike leakage:

ʻO ka ʻike ʻana i ka flaw magnetic, kūpono no ka ʻike ʻana i nā hemahema o ka ʻili a kokoke i ka ʻili o nā mea ferromagnetic.

D. Electromagnetic ultrasonic flaw detection:

ʻAʻohe mea hoʻohui e pono ai, hiki ke hoʻopili ʻia i ka wela kiʻekiʻe a me ka wikiwiki kiʻekiʻe, ʻoʻoleʻa a maloʻo hoʻi ka ʻili o ka paipu kila.

E. ho'āʻo komo wai:

ʻO Fluorescence, kala, a me ka ʻike ʻana i nā hemahema o ka paipu kila.

3. Nānā hana kino a me ke kemika o ka paipu kila:

4. Kaʻina hana nānā 'ana o ka paipu kila:

Huahana Huahana

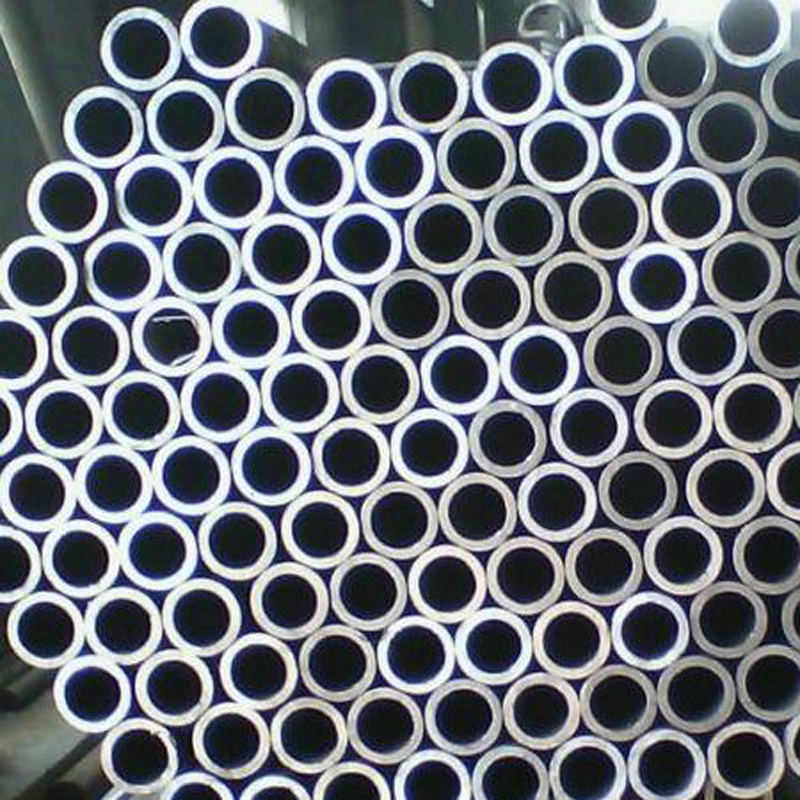

| Papa kila: | 106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT,ND-Steel Paipu |

| Kūlana: | ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,9 DIN17457,9 DIN ,BS3605,BS3059 |

| Hōʻike: | Ka lōʻihi o waho 10~508mm |

| Wt: | 1.0-30mm, a i ʻole e like me ka noi kūikawā o ka mea kūʻai aku |

| Ka lōʻihi: | 2-20meters, a i ʻole e like me ka noi kūikawā o ka mea kūʻai aku |

| Pūʻolo: | Hoʻokuʻu aku i ka pūʻolo maʻamau |

| Nā ʻano o ka paipu: | Paipu paila, paipu pololei, paipu mīkini, paipu cylinder, paipu laina, etc |

| Mill MTC: | Hāʻawi ʻia ma mua o ka hoʻouna ʻana |

| Nānā: | Hiki ke ʻae ʻia ka nānā ʻana o ka ʻaoʻao ʻekolu, SGS, BV, TUV |

| awa mauna: | Kekahi awa ma Kina |

| Kau Kūʻai: | FOB, CIF, CFR, EXW, etc. |

| Kau Kūʻai: | TT a i ʻole LC i ka ʻike |

| ʻO kā mākou lawelawe: | Hiki iā mākou ke hana maʻamau e like me ka makemake o ka mea kūʻai aku a i ʻole ke kiʻi ʻana, hoʻopili e like me ka noi a nā mea kūʻai aku |

Hōʻike Hale Hana